There are, in this world, those fussy folks who don’t want you to walk on the grass.

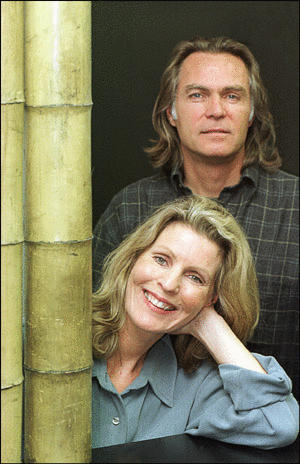

But then there are Ann and David Knight, who are building a business of grass for walking.

The Knights are not talking lawns, though. Their business is TimberGrass, purveyor of fine bamboo floorings and panels.

“People buy this because it’s beautiful, durable and sustainable,” said Ann Knight. “The wood is harder than oak or maple, more stable, and you don’t get a lot of gapping between the boards.”

The business has grown fast enough that the Knights have moved out of their Manitou Beach garage and into the Day Road Industrial Park, taking over some of the space recently vacated by Watson Furniture Systems’ move to Poulsbo.

Bamboo’s primary attraction is renewability – it grows fast, and what is harvested is just the stems, like a giant stalk of grass.

TimberGrass flooring and paneling is made from a bamboo variety called Moso, that is grown in mountainous areas of China’s Zhejiang Province.

“It’s the hardest bamboo,” Knight said. “It gets snowed on and rained on, but it grows to 80 feet high in six years, compared to 120 years for hardwood trees. You have to harvest it then, or it goes to seed.”

The bamboo, grown by independent farmers, is milled and made into flooring and paneling at a factory in China, using processes developed by islander Steen Ostenson, who founded TimberGrass in 1994.

The manufacturing process involves binding thin layers of bamboo into tongue-and-groove flooring panels, generally 5/8ths of an inch thick. The grain can be vertical, which creates a traditional grained look, or horizontal, which displays the characteristic “knuckles” of bamboo stalks.

TimberGrass says tests show that the resulting material is harder than either oak or maple, and less subject to warping as weather changes, and that the adhesive used in the lamination process has virtually no free formaldehyde.

Despite the amount of labor required, costs are competitive with most other hardwood flooring material, Knight said – about $10 to $12 per square foot installed.

New products include panels for wall treatments and counter tops, as well as for moulding and window-trim, Knight said.

“The only thing we don’t recommend it for is outside. Because it is a natural product, it will bow if it gets wet enough.”

David Knight is originally from Arizona, where for a time he ran a family fluorspar mine. After moving to Bainbridge Island and marrying Ann, who had an administrative background, the couple formed Medical Dental Development Services, which consulted with medical practices and specialized in consolidating them.

They joined Ostenson at TimberGrass in 1998, just as the green-building movement was beginning to take off in the Northwest.

“We had a little booth in the Seattle home show in 1998,” Ann said, “but now, there is a whole section for green building.”

The TimberGrass flooring was on display locally at an Eagle Harbor area home on the May, 2000, Bainbridge Performing Arts home tour. Presently, the flooring is featured in one room of the Sunset Magazine Idea House in Redmond, open through Nov. 18.

The flooring is also being used in the classrooms at Puget Sound Environmental Learning Center, according to Ann Knight, and was used in a portion of Bloomingdale’s department store in New York City.

The Knights and Ostenson recently divided the business, with Ostenson working on product development and the Knights making TimberGrass into a distribution and marketing organization.

TimberGrass has recently hired four new employees, which forced the Knights out of their garage and over to Day Road.

The Knights’ new objective is to line up more distributors, and add to the current two warehouses, one in Kent and one in Cincinnati, to support anticipated growth.

“Our sales have doubled every year, and we think we can continue to do that,” Ann Knight said. “We’re also looking at expanding into Canada and Mexico. This is our baby.”